Aluminium Frames / Accessories

The main function of an aluminium frame system is to ensure the closure of a span efficiently, create visual harmony, illuminate and ventilate buildings, ensure the conditions of safety and comfort to its users.

It consists of aluminium profiles and their accessories.

Nortalu sells a complete line of accessories with high quality and performance.

The recommended accessories have been developed to allow the correct functioning of your systems.

Installation – Maintenance and conservation

The frame should be placed whenever construction work is completed to avoid contact with corrosive materials.

The frames must be secured using stainless steel screws and bushings of non-oxidisable material.

Watertightness between frames and walls should be ensured with the application of proven quality sealing products.

All aluminium should be cleaned to keep its surface in good condition. A soft cloth soaked in water will suffice.

In case of need, a neutral product diluted with PT water between 5 and 8 at a concentration of approximately 5% of the volume can be used.

Brushes, sandpaper, mops or any type of abrasive material should not be used, as well as solvent-based cleaning products (detergents, glass cleaners, thinners, among others).

Packaging and Transportation

A good packaging of the profiles is essential so that in the transport there are no deformations and scratches in the material.

The packaging, in many cases, is customized, according to the customer’s requirements or requirements of the profile itself.

The various types of packaging range from the simple application of paper between profiles, protection with plastic film to the packaging on wooden pallets.

After receiving the material by the customer, it should be conditioned in a closed place, where there is no moisture or dirt.

COMPLETED PROJECTS 2019

Clients

ALUMINIUM SYSTEMS

HAPPY TEAM

Construction System

Aluminium frame/Glasses

Our aim is to market tested systems, with quality assurance and safety recognised by the Directives of the European Community. The choice of a frame system should take into account some important aspects that may condition that choice.

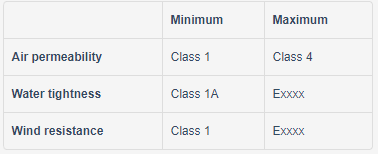

To ensure a characterization of the different available systems, three parameters were defined:

Air permeability (EN 1026)

It is the ability that a system presents, not to let the air pass, when closed and subjected to a pressure difference.

Resistance to wind pressure (EN 12210)

It is the feature that tells us the level of security guaranteed by the system to its users. The system is subjected to a series of pressures and depressions so that it is possible to measure the deformation of its profiles. In thermal break systems, we still test their acoustic and thermal insulation.

Water Tightness (EN 1027)

Defines the ability of a system to, when closed, oppose water infiltrations.

According to the European Regulations in place

The systems are classified according to the results obtained in lab tests:

Soundproofing

To ensure good performance, we must choose a system with good hermeticity and good sound attenuation values.

Thermal Insulation

If what we’re looking for is good thermal insulation, we should look for a thermal break system. The selection of a frame also depends on the dynamic pressure of the wind acting on the frame, the place of implantation and height of the building, and the aerodynamic roughness of the terrain.

Portugal is divided into two Major areas:

ZONE A: Almost the entire national territory, expect the regions that belong to zone B;

ZONE B: Azores and Madeira and the regions of the continent located in areas with altitudes higher than 600m and a coastal strip with 5Km wide.

ROUGHNESS can be divided into three types:

Type I: Downtown centers in urban areas with medium and large buildings;

Type II: Periphery of urban areas and rural areas;

Type III: Areas near cliffs or valleys.

Once all these parameters are defined, it is possible to calculate the dynamic pressure of the wind acting on the frames.

After selecting the frame system, we must take into account the glass to be used, since in most cases the largest surface of a span is glass.

There are several types of glass with different compositions that allow you to adjust to the most diverse requests and optimize the performance of the frame. Its characteristics can also be improved with the introduction of resins or films, with specific characteristics for the following cases:

• Solar Control

• Thermal Control

• Acoustic Control

• Security

• Energetic

• Luminosity

In the current context of energy legislation, the selection of the frame+glass set, assumes greater relevance for an ideal classification of the building

Solar Control (Low Emissive)

To ensure greater energy savings, the amount of energy passing through the glass into the housing should be reduced.

Soundproofing

In the case of good soundproofing, we have to take into account that, in addition to choosing a glass with these characteristics, the glass blades must have different thicknesses and the greater this difference, the better insulation we will have.

Seals

The choice of the type of seals is determinant for its durability, allowing to maintain its main characteristics over time, without showing signs of aging or deterioration.

One of the most important aspects of the operation and behaviour of frames is related it’s sealing.

The quality of the seals to be used in its construction becomes essential to ensure perfect watertightness.

Water tightness and drainage

For a good watertightness and drainage of the frames it is necessary to make a good sealing of all the frames and connections between profiles.

Drainage tears should be made in the horizontal lower profiles, avoiding the appearance of condensations and small infiltrations inside the profiles.

To avoid the risk of wind reflux, the outer tears must be protected by leaks that allow water to flow and prevent wind from entering.

Assembly of frames / glasses

When assembling the frame, it´s always necessary to take into account that the connection between profiles and the union of frames should be executed with recognized quality accessories and stainless steel screws.

Frames and profile connections must be properly sealed with appropriate silicones or glues.

The placement of the glasses must be in accordance with the technical specifications indicated by the glass supplier, always on shims in order to avoid direct contact of the glass with the frame and ensure correct positioning. It should be applied with appropriate seals for good watertightness.

SUBSCRIBE TO OUR E-MAIL LIST

STAY UP TO DATE FROM THE NORTALU NEWS!

Contact us!

![]() Address: Rua Dr. José Bragança Tavares, 78 Fr. A 4580-593 Paredes (Mouriz)

Address: Rua Dr. José Bragança Tavares, 78 Fr. A 4580-593 Paredes (Mouriz)

![]() Telephone: 255 781 548/49

Telephone: 255 781 548/49![]() Mobile: 92 705 80 65

Mobile: 92 705 80 65

![]() Email: nortalu@nortalu.com

Email: nortalu@nortalu.com

© 2021 Nortalu, Comércio de Alumínio, Lda. All Rights Reserved.